Graphic Description of How Portage Bridge is Being Rebuilt

Work Being Done with Machines Manipulated by Air.

Portage Bridge, NY May 27.

The work of rebuilding the famous Portage bridge is attracting a great deal of attention and although signs are display forbidding persons going actross the bridge there are many who pay no heed to the signs and the authorities are endeavoring to arrange some method so the workmen will not be hampered by excursionists at the opening of the season on Memorial Day.

About twenty men are employed on the bridge at the present time and although more will be put on soon, it is expected that it will take nearly six months to complete the bridge all told.

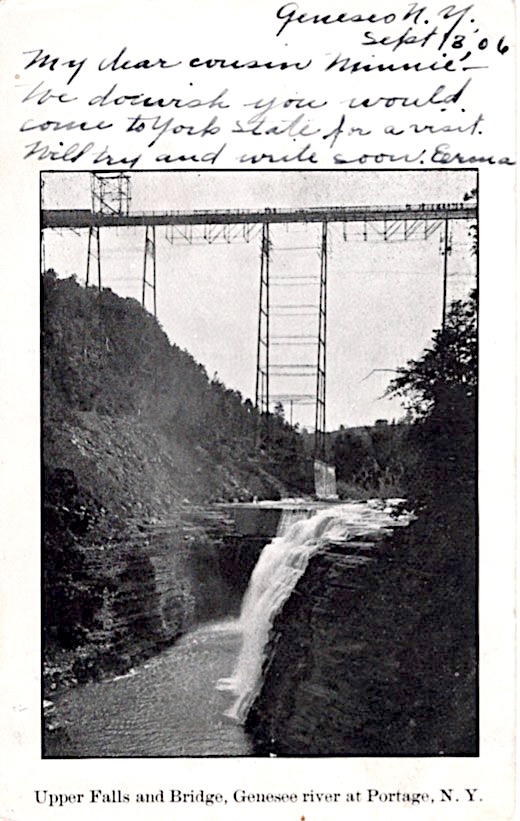

The work of rebuilding the bridge is a sight to behold. This bridge is 236 feet high and for many years it bore the disctinction of being the highest bridge in the world. Perched on little scaffods in mid air with the rushing waters of the Genesee River beneath them, the men are at their dangerous work.

Three cars are side-tracked at the end of the bridge, two of them being used for tool houses and the other containing a wqe horse power gasoline engine installed upon it. This engine runs from morning until night pumping air into the immense reservoir, from this reservoir is attached a two inch iron pipe which runs out into and across the bridge. This air pipe is tapped and a hose fitting attached, Then a wirebound rubber hose is attached and is run down the towers where the men are at work on rough scaffolds made of two boards, ten inches wide and about 10 feet from the op of the bridge, making it over 200 feet from the water.

At this point the workmen are drilling holes in the towers to put a double row of rivets in the powers at a point where the new girders are to be fitted in. All of the short spans are to be fitted with new girders made of steel, 6 feet wide, set edgewise and the towers are to be strengthened by extra rivets, for which they must drill seven-eight holes through the angle plate and the main plate of the tower, thus making one and one eighth inches of solid steel to be drilled through. |

|

The machine for drilling has a presser screw and running at right angle through the center is a gas pipe for handles is the hose leading to the air pipe above. Two men pick up ther drill portion of the machine and one man tends to the presser screw while another opens a valve, allowing the air to place the drill in motion and in 59 seconds a seven eighth hole is bored through one and one eighth inches of solid steel.

The rivets are put in by air also. One man has a portable forge up on top and he heats a rivet red hot and drops it down to the man of the scafold waiting for it. This is one of the dangerious “tricks of the trade” for the man must catch the red hot rivet. But he uses an old paint pail in which there is a lot of dirt to make the catch. Then with a pair of tongs the man put the rivet through the hole from the back side and another man takes a large bar shaped like a letter J with a socket in the point of the crook which fit over the head of the rivet. The man then puts this bar on the rivet which he is able to hold as solid as it it was anvil. Then another workman takes an old fashoned “grandfather’s” horse pistol in the muzzle of which is a small plunger with a play of 9 inches. When the air is let in the inside plunger strikes the one at the muzzle a blow of 90 pounds. The man then holds the muzzle against the hot rivet and pulls the trigger. In just ten seconds a head is made on the rivet as true as it if had been turned in a lathe. This all has to be done of course while the rivet is hot. Considering that it is all being done in mid air, it is a most wonderful undertaking. F.W.

Left: This postcard, postmarked September 4, 1906, may have been taken during the 1903 renovation project on the Erie Trestle. |

|